Information: This article was published in International Journal of Information Security and Cybercrime, Vol. 13, Issue 1, 2024.

Link:

Download:

“Both pure and applied science have gradually pushed further and further the requirements for accuracy and precision. However, applied science, particularly in the mass production of inter-changeable parts, is even more exacting than pure science in certain matters of accuracy and precision.”

Walter Shewhart

1. Quality, an omnipresent characteristic, with a profound impact on the entire economic and social life, recently celebrated a century since it was founded as a science.

Historians of the field appreciate that the modern quality was born a century ago, on 16 May 1924, when the young engineer Walter Shewhart introduced the first control chart, which launched the statistical process control and the quality improvement.

According to the great quality guru Deming, Shewhart’s invention of the control chart in 1924 has been considered as one of the greatest contributions to the philosophy of science [8].

Walter Shewhart was the pioneer and visionary of modern quality control. Consequently, he has a special place in the list of the most important “quality gurus”.

2. I have extensively presented the personality of Walter Shewhart and his contributions to the development of quality as a science in an extensive article that I published a decade ago [1]. This paper was based on original documents that I obtained both from companies that had an essential role in the development of quality, and from Shewart’s descendants, especially from Darin Sekulic, Shewhart’s great-grandson, to whom I renew my thanks on this occasion.

Next, I will briefly present the main contributions of Shewhart, as well as the way in which they were received by the qualiticians of the era.

Shewhart attended the University of Illinois receiving an A.B. in 1913, then an A.M. degree in 1914. He was awarded his doctorate from the University of California in 1917.

In 1918, Walter Shewhart joined the Western Electric Company, a manufacturer of telephony hardware for Bell Telephone. Bell Telephone’s engineers had been working to improve quality and reliability of their transmission systems. Bell Telephone had already realized the importance of reducing variation in a manufacturing process, the basis of all lean production. Moreover, they had realized that continual process-adjustment in reaction to non-conformance actually increased variation and degraded quality [4], [5], [10].

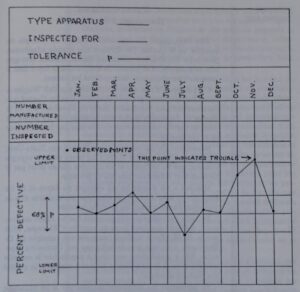

In 1924, the young engineer Shewhart framed the problem in terms of “assignable-cause” and “chance-cause” variation and introduced the “control chart” as a tool for distinguishing between the two. Shewhart stressed that bringing a production process into a state of “statistical control”, where there is only chance-cause variation, and keeping it in control, is necessary to predict future output and to manage a process economically.

Shewhart worked at Bell Telephone Labs on statistical tools to examine when a corrective action must be applied to a process. His writings were on statistical control of industrial processes and applications to measurement processes in science. The control chart techniques which he developed have been widely adopted [6], [7].

3. As I have already mentioned, in May 1924 Walter Shewhart introduced the first control chart, as a method to determine when a process was in a state of statistical control. Shewhart’s methods were the basis for statistical process control (SPC) – the use of statistically based tools and techniques for the management and improvement of processes.

Walter Andrew Shewhart (1891 – 1967) – the “father” of modern quality

When Shewhart joined the Inspection Engineering Department at Hawthorne in 1918, industrial quality was limited to inspecting finished products and removing defective items; but that all changed in May 1924. The chief of Walter Shewhart, George Edwards, described this event: “Dr. Shewhart prepared a little memorandum only about a page in length. About a third of that page was given over to a simple diagram which we would all recognize today as a schematic control chart. That diagram, and the short text which preceded and followed it, set forth all of the essential principles and considerations which are involved in what we know today as process quality control” [5].

Dr. George Edwards had observed the birth of the modem scientific study of process control. That same year, Dr. Shewhart created the first statistical control charts of manufacturing processes, which involved statistical sampling procedures. Shewhart published his findings in a 1931 book, Economic Control of Quality of Manufactured Product [9].

Shewhart worked to advance the thinking at Bell Telephone Laboratories from their foundation in 1925 until his retirement in 1956, publishing a series of papers in the Bell System Technical Journal.

During the 1930s, Shewhart’s work led him to fundamental scientific and philosophical issues, particularly those concerned with operationalism [10].

While Shewhart’s ideas on control charts were adopted at Western Electric, they had limited impact outside the company until the late 1930s when he started working with W. Edwards Deming at the War Department of the United States. Deming and other engineers and statisticians worked with the War Department, creating a series of sampling inspection plans in quality field, that were published as the MIL-STD (military standard) series.

In 1939 Shewhart published the important book Statistical Method from the Viewpoint of Quality Control. The publishers of this book mentioned that: In this classic volume (…) Dr. Shewhart illuminates the fundamental principles and techniques basic to the efficient use of statistical method in attaining statistical control, establishing tolerance limits, presenting data, and specifying accuracy and precision [8].

In order to aid a manager in making scientific, efficient, economical decisions, he developed Statistical Process Control methods. Many of the modern ideas regarding quality owe their inspiration to Dr. Shewhart. He also developed the Shewhart Cycle Learning and Improvement Cycle, combining both creative management thinking with statistical analysis.

Walter Shewhart was the pioneer and visionary of modern quality control. Shewhart’s name opens the select gallery of the great names in the history of modern quality. This gallery contains the names of the great ‘gurus’ of quality, among which we could mention: Edwards Deming, Joseph M. Juran, Kaoru Ishikawa, Philip Crosby, Armand V. Feigenbaum a.o. During the 1990s, Shewhart’s genius was re-discovered by another generation of managers, through intermedium of the “Six Sigma” approach.

4. As mentioned in [11] in the first part of the last century, quality was defined as “conforming to the standards and specifications of a product” Thus, the commonly adopted quality practices by industries were the standardization of quality, inspection, and rework. Deming emphasized that “quality is to fulfill the requirements of customers and satisfy them” [8]. Hence, the meaning of quality was gradually changed to a “customer‐focused” perspective. Enterprises, therefore, committed themselves to satisfy customers’ needs and expectations. Their aim was to pursue customer’s satisfaction and loyalty. Companies also developed a number of methods to find out customers’ needs and expectations. But, when some important companies announced several innovative products, and their sales were increasing, it became apparent that only satisfying customers’ requirements are not enough. As a matter thereof the identification and fulfillment of customers’ unsatisfied latent needs was gauged in conjunction with their emotional responses [11].

Concerning the future of quality, some authors consider that Quality 4.0 is the next natural step in the evolution of this field. It is based on a new paradigm that enables smart decisions through empirical learning, empirical knowledge discovery, and real-time data generation, collection, and analysis [12]. As Quality 4.0 matures and different initiatives unfold across manufacturing companies, intractable engineering problems will be solved using the new technologies. Advancing the frontiers of manufacturing science, enabling manufacturing processes to move to the next sigma level, and achieving new levels of productivity is possible. Quality 4.0 is still in a definition phase where different authors have different perspectives on how to apply the new technologies.

An interesting new concept – Learning Quality Control (LQC) – was introduced in [12]; this is a process monitoring system based on Machine Learning and deep learning; LQC focuses on real-time defect prediction or detection. The task is formulated as a binary classification problem, where historical samples (X, l) are used to train the algorithms to automatically detect patterns of concern associated to defects (e.g., anomalies, deviations, non-conformances).

5. In the hundred years of its existence, quality was a dynamic concept, which constantly evolved: in the first decades of its existence, the focus was on the issue of inspection and statistical control of product quality (the corresponding procedures being developed); in the 1960s … 1970s, the focus began to shift towards the quality assurance of products and services. In the 80s, the Total Quality Management (TQM) concept was founded, and starting with the 90s, an increasing importance was given to the certification of management systems: the appearance of standards aimed at the certification of quality management systems from the ISO 9000 series and those that followed them (ISO 14000, IS0 45000, ISO 27000 etc.) is considered a real revolution in the field.

In the current view, quality is considered a vector quantity, having a static component (conformity) and several dynamic components (reliability, maintainability, security, survivability, a.o.) whose importance has varied over time. Reliability began to be substantiated as science starting with the 50s, maintainability – starting with the 60s, and security/safety starting with the 70s.

Currently, the importance of security has increased, especially that of cyber-security, but also that of resilience.

6. Of course, along with the development of new disciplines in the domain of quality and dependability, there was also the problem of training specialists in these emerging fields through the development of appropriate undergraduate and post-graduate educational programs.

The first educational programs in the field of quality were held in the fifth and sixth decades of the previous century at the company level by quality “gurus” and by their consulting teams.

After 1965, several reliability education programs were developed at various American universities, including the Air Force Institute of Technology Dayton, Ohio, U.S. Naval Post-Graduate School Monterey, California, University of Phoenix, Arizona, Princetown University, New Jersey and Columbus University, New York.

In this context, it is noted that in Romania, especially within the Polytechnic Institute / University Politehnica of Bucharest (PIB / UPB)* – the largest technical university in Romania – there have been valuable educational initiatives in the field quality and dependability, which places it at the forefront at European and even global level.

An essential role in the development of educational and research programs in the field of quality and reliability in the field of electronics, telecommunications and information technology was played by the Department (Chair) of Electronic Technology and Reliability (ETR) of the Faculty of Electronics and Telecommunications (ElTc – PIB), founded in 1971, at the initiative of Professor Vasile Catuneanu [2].

As a founding member of the ETR Department, I am proud that in the more than five decades of professional activity that I have dedicated to the development of the department and the field of quality and reliability, I have contributed to the development of numerous graduate and postgraduate programs in this domain.

The most important postgraduate programs that I have initiated and coordinated are the Postgraduate Academic Program “Quality, Reliability, and Maintainability of Complex Systems” (1980 – 2008) and the master’s programs “Quality and Reliability Engineering” – ICF (1996 – 2006) and “Quality and Dependability in Electronics and Telecommunications” – ICSFET (starting with 2006). A detailed presentation of these programs is made in [2].

7. The new political and social context in Romania after 1989 led to the emergence of several foundations and non-governmental organizations, in the broad field of quality, among which we would like to especially mention the activity of RAISA.

Indeed, in November 2012 – when the concepts related to this field were not yet sufficiently well implemented (at least, at the level of Romania), at the initiative of a group of enthusiastic and dedicated professionals to the IT security field from the EUROQUALROM Laboratory of the Faculty of Electronics, Telecommunications and Information Technology (FETIT) of the University “Politehnica” of Bucharest (including two university professors with experience, pioneers of the dependability field in Romania) and from the Police Academy “Alexandru Ioan Cuza” Bucharest has founded the Romanian Association for Information Security Assurance – RAISA, a professional, non-governmental, non-partisan political, non-profit and public benefit association [3].

During the years since then, other experts from academia, research, the corporate environment, and public administration – mainly PhD graduates in the field – have joined RAISA’s efforts to promote cybersecurity at the national level.

All those involved in the development of RAISA understood the importance of the domain, the unique perspectives of the development of the field and the fact that only the implementation of a vast culture of cybersecurity can contribute to its success.

Appendix. The birth certificate of modern quality

This internal note of Western Electric/Bell Laboratories, sent by Walter Shewhart to his chief, Reginald Jones on May 16, 1924 (presented here in facsimile) is a historical document, kept in a special place in the archives of the society, in New York [10]. It proposes the first diagram for statistical control of quality on production flow and therefore can be considered as the birth certificate of modern quality.

|

|

References

-

- I.C. Bacivarov, Nine Decades of Modern Quality. Walter A. Shewhart – A Pioneer and Visionary of Quality, International Journal of Information Security and Cybercrime, vol. 3 (2014), no.1, pp. 9-16.

- I.C. Bacivarov, The Department of Electronic Technology and Reliability from the University Politehnica of Bucharest – 50 Years. Five Decades in the Service of Education and Scientific Research in the Field of Quality and Dependability, International Journal of Information Security and Cybercrime, vol.10 (2022), pp. 91-109.

- I.C. Bacivarov, The Romanian Association for Information Security Assurance (RAISA): Ten Years in the Service of Cybersecurity – Editorial, International Journal of Information Security and Cybercrime, vol.11 (2022), pp. 7-18.

- I.C. Bacivarov, “Monștrii sacri ai calității: Walter A. Shewhart”, Calitatea – Acces la success / Quality – Access to Success, no. 2, 2001.

- Walter Andrew Shewhart: http://www-groups.dcs.st-and.ac.uk (accessed March 20, 2024).

- D. Fagen (ed.), A History of Engineering and Science in the Bell System: The Early Years (1875-1925), 1975.

- Bayart, W.A. Shewhart, C.C. Heyde and E. Seneta, Statisticians of the Centuries, Springer Verlag, New York, 2000, pp. 398-401.

- Deming, W., E. Out of Crisis. 1986; Cambridge, MA: MIT Press.

- Shewhart, Economic control of quality of manufactured product, New York: D. Van Nostrand Company, 1931.

- Western Electric History: https://memorial.bellsystem.com/westernelectric_history.html (accessed May 10, 2024).

- Ching-Chow Yang, The Evolution of Quality Concepts and the Related Quality Management, in https://www.intechopen.com/chapters/53946 (accessed May 5, 2024).

- Escobar, C. A., Morales-Menendez, R., Machine Learning in Manufacturing: Quality 4.0 and the Zero Defects Vision. To appear in Elsevier (2024).